| |

Quickly take designs from concept to production

Key Benefits

• Speeds designs from placement and routing through to manufacturing

• Includes powerful features such as design partitioning, RF design

capabilities, and interconnect design planning

• Production proven to increase productivity and help engineers quickly

ramp up to volume production

• TÜV SÜD “Fit for Purpose – TCL1” certified to meet ISO 26262 automotive

functional safety requirements

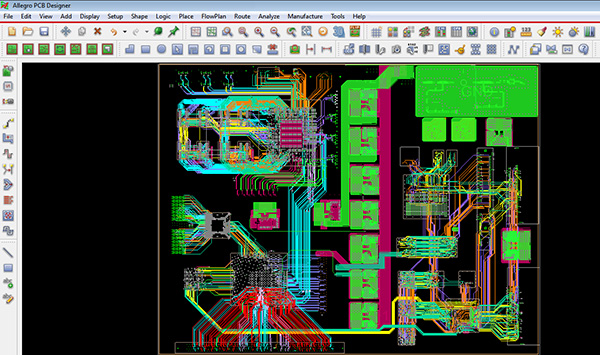

The Cadence® Allegro® PCB Designer

quickly takes simple and complex designs

from concept to production in a

constraint-driven design system to ensure

functionality and manufacturability.

Scalable technology allows designers to

cost-effectively match all current and future

technological and methodological needs for

teams, organizations, and projects of all sizes

and complexities.

The industry's latest bleeding-edge high-speed

design, RF antenna, flex-circuitry, and design

for manufacturing (DFM) technology in the

Allegro PCB Designer gives you what you need

to deliver the innovative products your customers

demand. And the advanced design reuse and

productivity features give you the advantage you

need to beat your competitors to market. |

Speed designs from placement and routing

through to manufacturing with powerful

features such as design partitioning, RF

design capabilities, and interconnect

design planning. |

Automotive TCL1 Certified for ISO 26262

The industry’s first PCB design and verification flow to achieve “Fit for Purpose -

Tool Confidence Level 1 (TCL1)” certification enables you to meet stringent ISO

26262 automotive safety requirements. The flow includes everything from design

authoring to simulation to physical realization and verification using the PSpice®,

Allegro, and OrCAD® product suites. The high-performance design entry,

simulation, and layout editing tools provide an integrated environment for design

engineers to validate the safety specifications against individual circuit specifications

for design confidence. For information on the safety manuals, Tool Confidence

Analysis (TCA) documents, and compliance reports from TÜV SÜD, download the

Functional Safety Documentation Kits through Cadence Online Support.

Features

• Provides a scalable, full-featured PCB design solution

• Enables a constraint-driven design flow to reduce design iterations

• Integrated DesignTrue DFM technology providing real-time DFM checks

• Provides a single, consistent, front-to-back constraint management environment

• Minimizes design iterations and lowers overall cost for flex and rigid-flex designs

with advanced rigid-flex design capabilities

• Enables dynamic concurrent team design capability to shorten design cycle by

dramatically reducing time spent on routing, tuning, and optimization of signals

• Delivers an integrated RF/analog design and mixed-signal design environment

• Provides interactive floorplanning and component placement

• Provides design partitioning for large, dispersed development teams

• Enables real-time, interactive push/shove etch editing

• Allows real-time plowing/healing with dynamic shape technology

• Manages net scheduling, timing, crosstalk, layer set routing, and geometric

constraints

• Provides proven PCB router technology for auto-routing of random signals

• Enables hierarchical route planning to accelerate design completion

• Shortens interconnect planning and routing time for dense designs with

high-speed interfaces

• Provides a comprehensive, powerful, easy-to-use suite of tools to assist

designers with an efficient and successful handoff to manufacturing:

• DFM Checker for signoff against company/manufacturing-partner-specific

rules

• Documentation Editor for reducing fabrication and assembly documentation

time up to 70%

• Panel Editor for communicating assembly panel design intent to manufacturing

partners

• Outputs design data in a variety of manufacturing formats

|