| |

Improve systematic and parametric yield and meet foundry DFM signoff requirement

Key Benefits

• Improves systematic and parametric yield

• Meets DFM foundry requirements

• Integrates with Cadence custom and digital design platforms

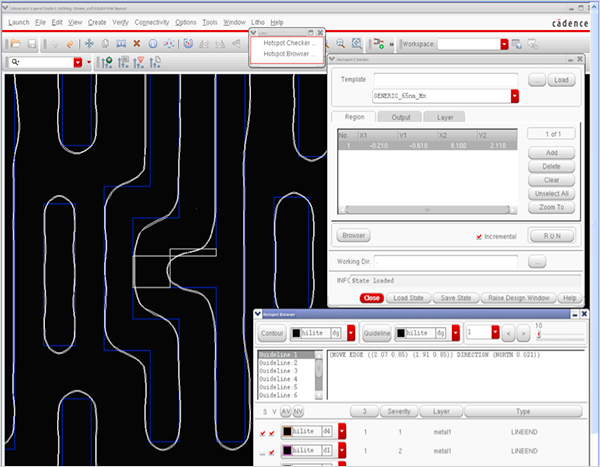

Cadence® Litho Physical Analyzer detects and corrects lithography hotspots, and does so quickly, based

on either fast, accurate silicon contour prediction, or high-performance pattern matching.

Litho Physical Analyzer detects manufacturability issues missed by traditional physical verification.

Depending on the foundry enablement, the tool can either perform a pattern-based check or use a

simulation engine to meet foundry litho requirements. Litho Physical Analyzer not only provides foundry-

certified fast-litho detection for signoff, it also allows hotspots to be detected during implementation

through tight integration with custom and digital implementation platforms. The solution provides fixing

guidelines to increase automated fixing rates.

In addition to litho checks, Litho Physical Analyzer can perform pattern-based layout optimization to

improve design quality, increase usage of DFM rules, and automate the fixing of complex design rules.

Key Features

• Provides fast, scalable and foundry-certified detection of yield-limiting hotspots to meet litho

signoff requirements

• Produces fixing guidelines to increase automated fixing rates

• Integrates with current library, IP, custom analog, and cell-based digital physical design flows

• Delivers versatile pattern-based layout optimization to improve design quality

|